Lyco is a US based world-leading manufacturer of commercial cooking and cooling machines. They work with pasta, rice, dry beans and vegetables. They are the most innovative company in their field and have sold over 750 machines. Lyco was founded in 1980 and their equipment is operating with virtually every leading food processor in North America and many around the world including Australia and New Zealand.

Cooking, Blanching and Cooling Equipment

Lyco’s Heating and Cooling Equipment increases recovery and yields better looking product with less damage in comparison to other industrial food cooking and cooling equipment. Achieve total consistency with uniform heating and cooling of food products. This results in a safer process and a colder final product temperature which increases shelf-life.

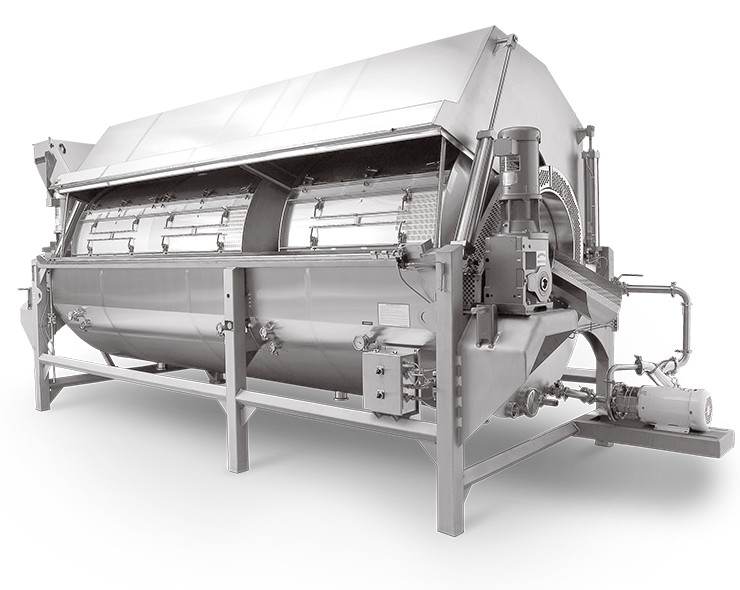

Rotary Drum Blancher

Since 1985 Lyco has been the most innovative company in the food industry. Their blanchers, cookers and coolers are the most advanced, state-of-the-art machines in the world. They have increased capacity, reduced process times, and eliminated under-cooking and over-cooking and reduced cooling times by 40% in rotary drum machines. Lyco designs use less energy, less water and produce higher quality in a smaller footprint.

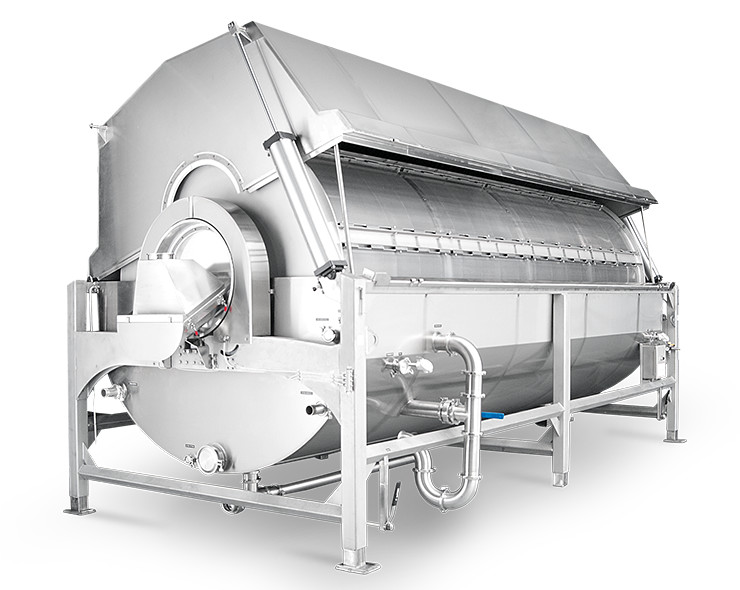

Cooker Cooler

Combination blancher/cooker-coolers were first designed in 1995 for blanching and cooling pasta, rice and vegetables. The basic process differences between a blancher, cooker or pasteurizer are retention times and operating temperatures. Lyco Cooker-Coolers have the option of doors in the cylinders and clean-in-place manifolds in the cover, the open centre flights, and the tank sides. Lyco combination cooker/coolers have lower maintenance costs and take up much less room than two separate machines and a conveyor in between. The single CIP System cleans both hot and cold zones. Save major floor space with this design.

Vapor-Flow Steam Blanchers

Vapor-Flow Steam Blanchers can switch over from steam to water cooking by simply turning a valve and draining the water from the tank. Water blanching hydrates products, but steam cooking uses 50% less energy and 90% less water. Steam can also increase recovery by 1 to 3% by leaching out fewer solids and nutrients.

Clean-Flow Steam Blanchers

Lyco Clean Flow Blanchers were developed in 2007 to address the need for faster sanitation cleanup time so that prepared meal operations could run many different products in a day. The Clean-Flow in Place System can clean over 98% by itself. All Clean-Flow designs feature Hydro-Flow® agitation, which guarantees a uniform process. You’re able to achieve a much higher quality product because every food item is individually treated gently. Under- and over-cooking of pasta is eliminated. Losses from sticking and clumping are totally eliminated which increases recovery 10% to 15% compared to European cook-quench-chill systems or batch kettle systems.

Clean-Flow designs have an auger with a wedge wire screen located underneath the auger from 3:00 to 9:00 o’clock which contains product between the auger flights during operation. For cleaning, the screen is driven by a large gear which rotates it 360° around the auger. Spray manifolds swiftly clean both sides of the screen and auger. Lyco machines are robust and made to very exacting tolerances, which result in very low maintenance, very high reliability and a higher return on investment. It has literally been called the best pasta, rice and vegetable blancher in the world!

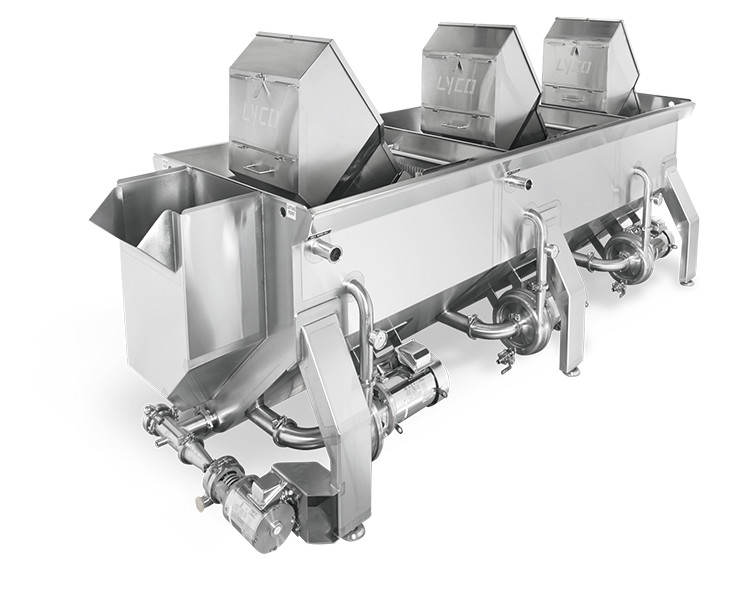

Easy-Flow High Speed Particulate Cooler

Lyco has revolutionized cooling particulate food items with a new design called Easy Flow. Traditionally certain pasta product took 12 minutes to cook, but they could be cooled to 4°C in 6 minutes. This machine is made in either a single zone or 2, 3, and 4 zones. Each zone submerges and mixes product in cold well water (13°C.) or chilled (1°C.) water where it rapidly discharges heat. The machine will handle any particulate food shapes. The first stage can cool most products from 93°C to below 21°C in under 10 seconds. A second stage cools product to 13°C, and the third stage brings product temperature down to 5°c or below. This is a tremendous improvement in food safety and productivity.

Iceberg High Capacity Particulate Cooler

The Lyco Iceberg high capacity particulate cooler processes a wide variety of foods from pasta and dry beans to vegetables within a compact footprint — only 1.8 metres x 1.8 metres x 2.4 metres tall. The Iceberg pre-cools in seconds ahead of freezing. The Iceberg works on all particulate foods and can handle up to 13,600 kilos per hour.

Chill-Flow Pouch Cooler

The Lyco Chill Flow pouch cooler cools product twice as fast. Prior to 1988 most pouch cooking was done on water deluge belts or spiral freezers. Chill-Flow™ Pouch Coolers are a variation of Lyco blancher/cooker/cooler designs used for the first time 28 years ago for cooling vegetables. Today they are used for cooling many different pouch sizes of sauces, pizza sauce, chowders and soups. Pouches may be a small pack of restaurant ketchup or up to 5 kilos. Final temperatures of 5°C are common requirements. Submerged water cooling is the most efficient and economical method of cooling volumes of pouched food products.

See Partner Website: www.lycomfg.com