APPEX 2024: March 12-15

February 2024 | News

APPEX 2024

Australasia’s Processing and Packaging Expo is an exhibition that will truly represent all sectors of the industry. It will provide a comprehensive range of all processing and packaging equipment and services under one roof.

As one of the leading suppliers of packaging and processing equipment across Australia and New Zealand, Automation & Packaging will be exhibiting in conjunction with their principals who make up part of Automation & Packaging’s portfolio of high quality packaging and processing equipment. We will have experts from Clevertech, Ronchi, Baumer and Zilli & Bellini available to discuss your requirements and present their latest developments and new innovations.

The Clevertech group, based in the north of Italy, designs, manufactures and markets engineered front of line and end-of-line solutions. Clevertech have numerous systems operating worldwide including Australia and New Zealand.

Clevertech will be available to discuss the latest developments in can and end making equipment, palletising systems and depalletising systems.

Ronchi Mario SpA are based in Gessate, Italy and are market leaders in the manufacture of Filling Machines, Capping Systems and Unscrambling and Orientating Systems for the cosmetic, chemical, pharmaceutical and food industries. Ronchi will be available to discuss new technical solutions these include the modular robotic bottle unscrambler and the new robotic cap sorter.

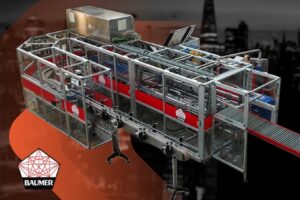

Baumer are based in Bologna Italy and have been manufacturing shrink wrapping machines and wraparound case packers since 1974 and supply machines to the food, beverage, dairy and personal care industries.

Baumer will be available to discuss their latest developments. These include their innovative Wrap-around case packer with the U-Shape Infeed System ™. This reduces the footprint of the machine by over 50% and can handle a wide range of products. Also the new Wrap-Around SF case packer which is less than 8 metres in length and can operate at up to 100 packs per minute with different cardboard types.

Zilli & Bellini was founded in 1962 and are based in Parma Italy. They are now one of the largest Italian manufacturers of filling equipment for the food industry.

A representative from Zilli & Bellini will be available to discuss their wide product range including telescopic fillers, vacuum fillers, piston fillers, gravity fillers, multifillers and seamers. Zilli & Bellini can also provide monoblock systems with either cappers or seamers.

As well as this we will also be available to discuss our full range of equipment which includes:

Lyco – Continuous cooking and cooling systems

Numafa – Washing systems

Steritech – Retort Systems

TecnoFerrari – AGV’s

TG Packaging – X-Fold wrappers

Clever Machines – Sleeve Labellers

Republic – Drying Systems

If you are planning on visiting APPEX, and would like to catch up with us to explore the newest innovations. Let us know (click here) and we will arrange a meeting time that suits.

We look forward to seeing you at APPEX 2024!

INTERPACK 2023

Between the 4th and the 10th of May Interpack will make its long awaited return in Düsseldorf. After 6 years of absence, the exhibition is expected to be bigger than ever, with ground breaking innovations presented by the global leaders in packaging and processing. At Interpack, Automation & Packaging’s principals will be unveiling some brand new innovations.

If you are planning on visiting INTERPACK, arrange to catch up with the Automation & Packaging team. Let us know (click me) and we will arrange a time that suits.

Lyco expands Continuous Blancher /Cooker/Cooler range

Lyco is the World’s leading manufacturer of continuous cookers, blanchers and coolers for pasta, rice and vegetables. They have manufactured these machines since 1985 and are recognised as experts in continuous cooking and cooling equipment. Lyco have over 750 units operating globally including Australia.

One of Lyco’s innovative products is the Clean-Flow® range of Cooker / Blanchers. These were introduced in 2007 and were named Clean-Flow® because they were specifically designed for the customer with multiple products and wanting maximum process flexibility.

With the integrated clean in place system CIP the Clean-Flow® reduces cleaning time to a minimum and provides a quick change over from one product to the next.

Lyco have had 40” and 50” diameter Clean-Flow units in operation since 2007 and last year due to customer demand they introduced a new smaller 30” diameter unit which is a game changer for processors with throughput rates of between 200 kg to 1,000kg per hour.

The Clean-Flow® has been called by a European processor “The best pasta cooker in the world!” this is partly due to the patented water agitation system the “Hydra-Flow®” that keeps product in suspension and all particulates separate right through the system so that you avoid any clumping and over or undercooked product.

With “Hydra-Flow®” agitation product yields can increase by as much as 10% compared to batch cook-quench-chill systems or older rotary drum blancher designs.

Clean-Flow® systems save labour, water, energy and reduce the yearly maintenance costs substantially.

For rapid product cooling the Clean-Flow® can be connected to another Lyco innovation the Easy-Flow® cooler which provides rapid cooling in a small footprint and can take products down from 94°C to 4°C in 30 seconds or less.

Lyco’s 5,000-square-foot testing facility located in Wisconsin USA is designed to allow the customer to run extensive tests, using their own products and at the same time see that Lyco stand behind their equipment.

For further information please contact Neil Durran (Automation & Packaging)

Lyco Clean-Flow cooker Lyco Clean-Flow and Easy-Flow cooler